Products

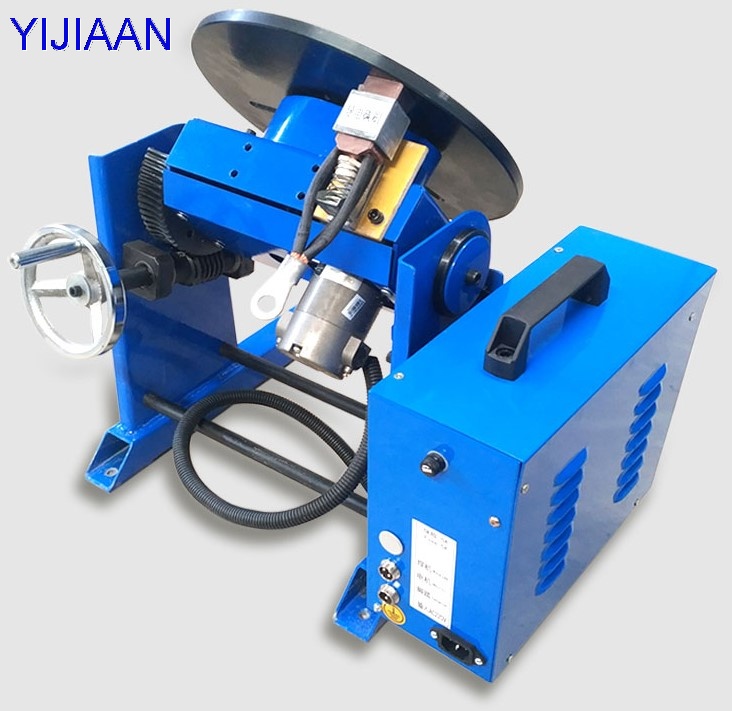

30kg flange joint rotating table for welding

1.310mm workbench

Thickness 12mm, durable wear

2. With XH10-210mm

Holding diameter 10-210mm

3. Time reset control box

Welder linkage, automatic welder

4.0-90 degree free rotation

Turbine worm, automatic locking

5. Quickly tighten and loosen

a pair of claws, positive and negative

6. Anti-high frequency circuit board

Prevent high frequency breakdown of argon arc welding

7. Rack spray treatment

Bright and fresh, never rust

8. Four-wire conductive carbon brush

High copper wear resistance and long life

9. With welding gun bracket

The welding gun is fixed and the weld is well formed.

Product Description

|

Model |

BWJ-30 |

|

Capacity(Horizontal/vertical) |

30/15KG |

|

Turning speed |

1-15r/M(0.5-7r/M) |

|

Input voltage |

AC220/110V 50-60HZ |

|

Worktable diameter/thickness |

310mm/12mm |

|

Carbon brush conductivity |

200A |

|

Adapter chuck |

XH125/200/300mm |

|

Out size |

380(L)*360(W)*400(H)mm |

|

Motor power/weight |

40w/32kg |

Positioner selection considerations:

1. When the positioner is used horizontally, it is selected according to the weight of the workpiece;

2. The maximum speed of worktable rotation , the motor of the same power, decelerates by the reducer, the lower the maximum speed, the greater the torque, the smoother the rotation;

3. Does the table diameter meet the requirements of the workpiece and whether the workpiece is eccentric;

4. welding current of welding machine , whether the machine's rotating electrical conductivity meets the requirements;

5. Motor control selection, you can choose DC voltage speed regulation, AC frequency conversion speed regulation, stepping or servo numerical control speed regulation;

6. Combine the positioner and the workpiece to actually select the size of the through hole in the middle of the machine;

7. Combine the actual need to select accessories such as chuck, gun holder, thimble, bracket and swinger and argon arc welding wire feeder;