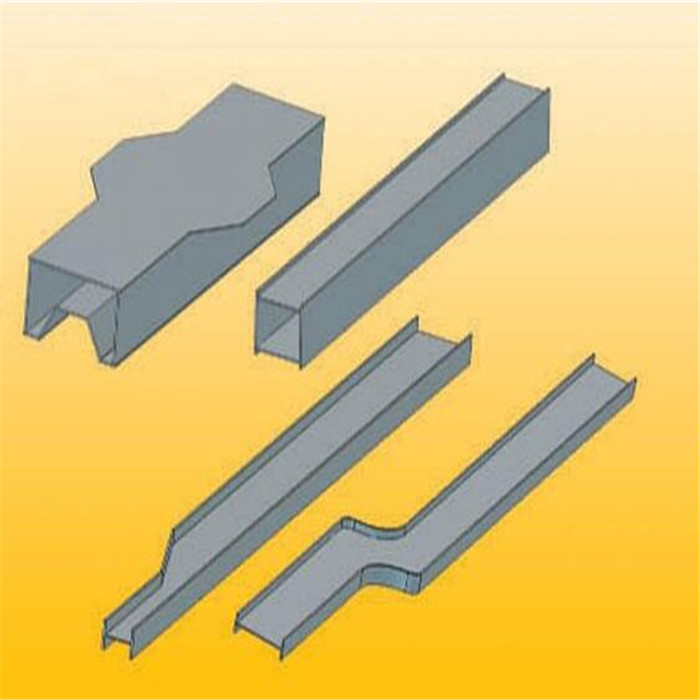

H beam double lines welding machine

1. The equipment can weld the parallel seams at one time, and have Very good effect for the welding of beams cross-section. It is the best equipment for car stringer welding at this stage.

2. the equipment adopts the automatic square technology which independent research and development by our company, can automatically track the welding gap, overcome the weld arc breaking phenomenon of cross-section welding, improve work efficiency, save the welding material.

3. This equipment adopts single-arc monofilament high-current submerged arc welding process, high welding efficiency, beautiful welding forming effect, deep penetration greatly increased the strength of the workpiece.

4. This equipment adopts the advanced microelectronics technology in current domestic and foreign , with convenient control, easy operation and so on.

Product Description

1.Gantry Longitudinal Welding Machine(Arc welding machine) can weld the parallel seams at one time, especially the irregular

beam(≤20°change section). It is one of the most useful arc submerge welding machines for the special vehicle industry at present

2.The gantry longitudinal welding machine adopts the advanced PLC program input technology and micro-electronics technology. It features in good welding quality, neat welding seam,operate easy and convenient, high efficiency and low costs.

3.The machine adopts the flexible and reliable profiling technology to fulfill the automatic seam trace and automatic adjustment. During the welding procedure, there is no trembling phenomenon and thus the working efficiency can be highly improved.

4.The CPU can process two groups of data and control the two torches to trace the star point and stop at the end. The machine has self-examination system when there is failure, the system can show you where the error lies. The machine features in good welding quality, convenient operation, and high efficiency. It can provide your product with a stable welding quality and can also make sure of the stable welding quality in the mass production.

The machine adopts the flexible and reliable profiling technology to fulfill the automatic seam trace and automatic adjustment. During the welding procedure, there

is no trembling phenomenon and thus the working efficiency can be highly improved.

|

Model |

QTGW18-2.8 |

|

Gauge |

2795mm |

|

Rail length |

18m( designed ) |

|

Effective Welding Length |

15m( designed ) |

|

Effective Welding Width |

200-600mm |

|

Return speed |

4m/min |

|

Welding speed |

1200-2500mm/min |

|

Welding wire diameter |

2.5-3-4mm |

|

Stroke(left and right) |

700mm |

|

Stroke(up and down) |

300mm |

|

Welding wire capacity |

25kg |

|

Welding flux reclaimer capacity |

100kg*2 |

|

Web plate width |

200-600mm |

|

Wing plate height |

50-300mm |

|

Wing plate thickness |

14-25mm |

|

Application |

Carbon steel, low alloy steel |

|

Welding style |

Flat angle welding |

|

Controller |

The AC Frequency Conversion Stepless-speed Regulator |

|

Power Supply |

AC 380V 50Hz |

|

Drive |

Double Side Drive |