Product Description

The automatic flat butt welding machine uses the cylinder keyboard, pressing the two boards on the special designed groove and the torch equipped with the water-coolant moving linearly welds the boards tighter.

The machine includes a long bench, a key compact device, a beam, a platform, a central orientation device, a pipe assembly and a welding cart. With the wire-feeder, the welding generator and the gas pipe can finish the welding work. The bench is strong enough to endure the compact pressure. The cylinder keyboard compacts the board equally. The welding speed is controlled by the DC motor, fulfilling the stepless adjustment and convenient operation.

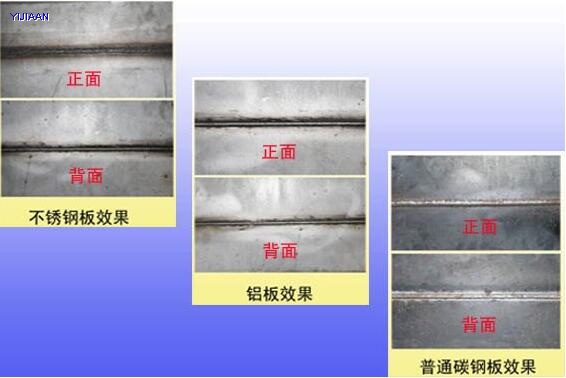

To ensure that the steel is flat, the seam can be welded for one side or for both sides. There is no minimal deformation. There are clean and beautiful seam on both sides, round and smooth transfers. The deviation on the back side is no larger than ±0.5mm, with the obverse no larger than 2mm and the reverse side 1mm. The width of the welding seam is 5-12mm

The Technical Statistics

|

The Welding Length(can be customized) |

9500mm |

The Adjustment of the Welding Speed |

The Stepless Adjustment |

|

The Welding Metal Base |

Q235A,16Mn,SUS304 |

The Welding Speed |

100-1500mm/min |

|

The Thickness of the Metal Base |

3-8mm |

The Operation Precision of the Welding Torch |

The Welding Torch can be Adjusted by Hand or Electromotion |

|

The Pressure of the Pneumatic System |

0.4-0.8MPa |

The Effect of the Welding Seam |

One-Side is Welded; Two Sides are Shaped. |

|

The Way of Pressing the Work Piece |

The Cylinder Keyboard Pressed |

The Dead Weight |

20ton |